Small updates to the Fenrir 3D printer hotend assembly

Hi everyone!

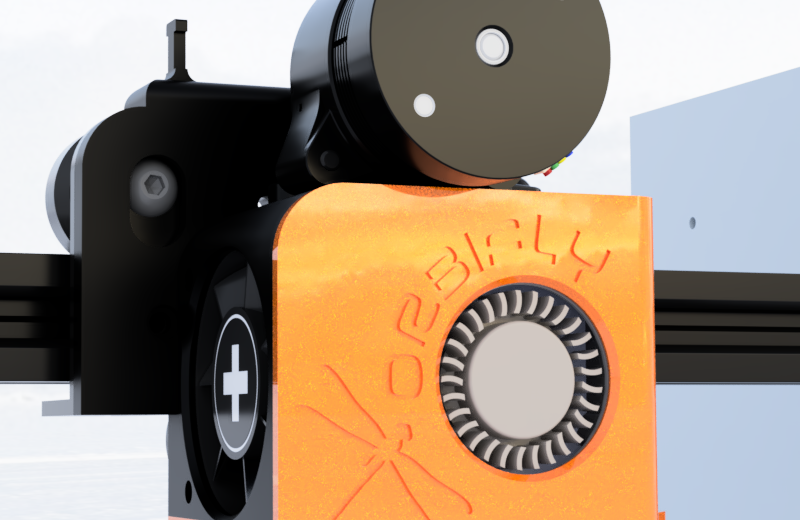

Some updates to the hotend assembly.

I’ve integrated the cable chain into the top part of the assembly and made slits to slide the black part into the orange part of the mount, and then a grub screw to secure everything, which should make it easy to service the hotend.

Other than that I will continue to print the Fenrir prototype parts, and try to get it done as quickly as possible, I really want to get it done so you guys can start building it.

Thomas.

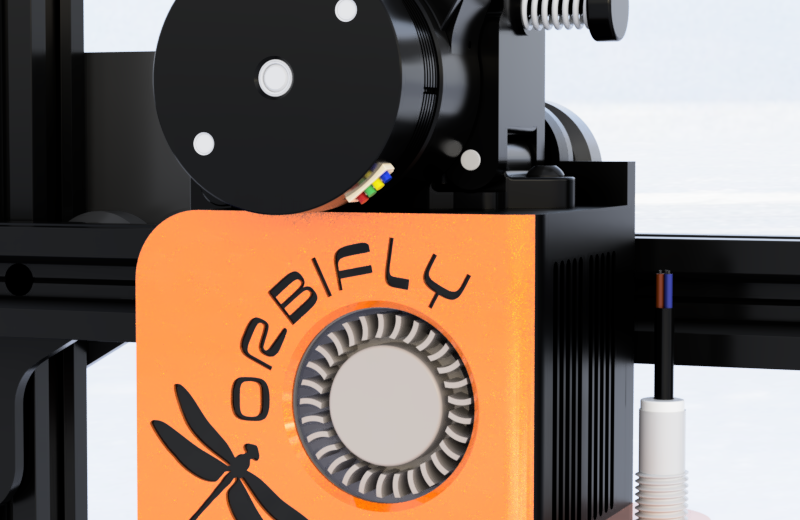

Fenrir has a new hotend assembly

Hi everyone!

I hope you all are doing well.

Sorry for the long time since the last update, I haven’t been home much the last month or two, so I haven’t had much opportunity to work on projects. I’m now finishing up the new E3D Revo Micro hotend assembly for Fenrir and will continue building the prototype asap. I can’t wait to finish it up, and then see it built around the world!

Check out the renders of the new Revo Hotend assembly, I hope you like it.

Thanks,

Thomas aka MakerViking

Fenrir CoreXY update!

Hi all!

This month most of my time has gone to working on Fenrir.

I got the components I needed from LDO and I’ve been focusing on tweaking the design to the specific components, printing prototype parts, and editing as needed to make things easier to print, more rigid, tweaking etc.

I’ve also made a fan bracket with ducts to the Nema14 A and B motors, to avoid any heat issues that might arise, this fan bracket actually also makes it easier to print the top, more specifically support removal is way easier now!

Currently, I’m printing the updated top, and working on a few more things on the other parts. I’ll continue printing them as the parts get done.

The launch of Fenrir is getting closer and closer! 😀

I would like to thank you all for the support!

Thomas the MakerViking

A slight delay because of covid

Hi all!

I had planned to post the Orbifly files by now, but I’ve been sick for a couple of days and I tested positive for Covid yesterday, which explains why. This has resulted in the slight delay mentioned in the title. I do expect to soon feel better again, so it won’t be long before the files are available.

Thanks,

Thomas the MakerViking

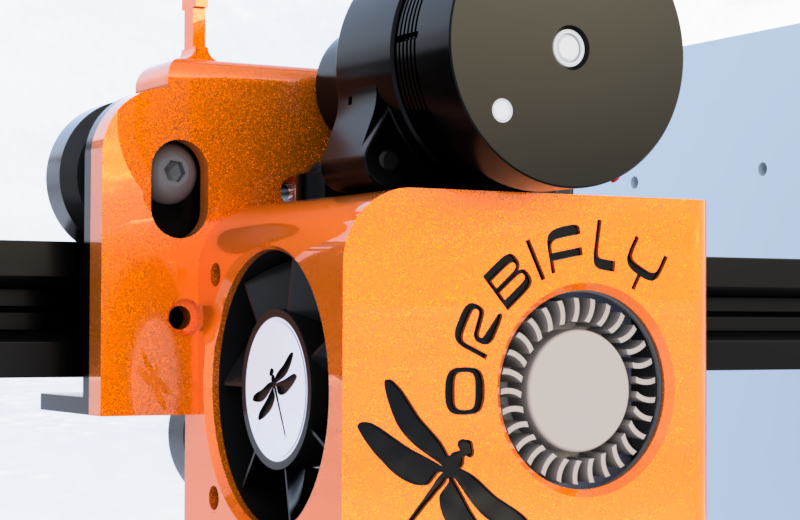

Orbifly – Direct Drive mount

Here’s an update on the Direct Drive mount I’m hereby calling Orbifly, for printers with the Ender 3 style mount.

This mount uses the Orbiter and Phaetus Dragonfly BMO, and also has an integrated Pinda probe v2 mount.

I plan to make a version for both Orbiter 1.5 and 2.0.

I will be releasing the files in a few days to all Patreon tiers.

Thomas the MakerViking

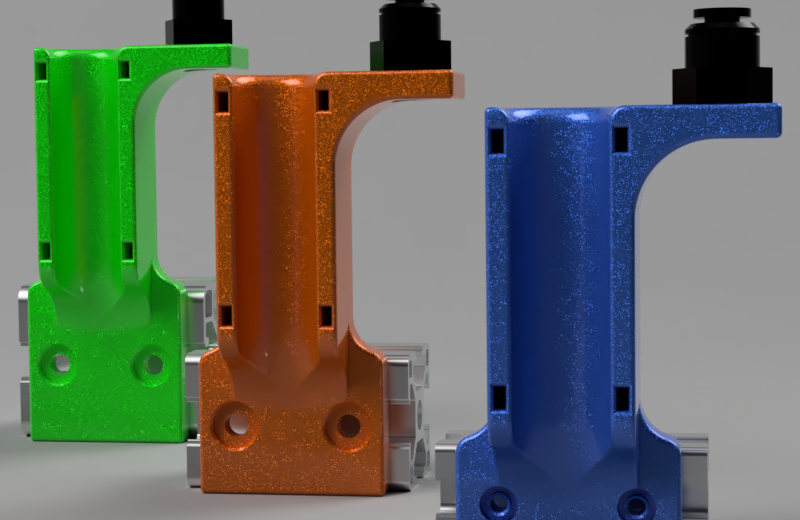

Orbiter + Phaetus Dragonfly BMO – Direct Drive mount

Hi all,

I’m working on this Direct drive mount for the Ender 3, Pro, and other printers with a similar hotend bracket.

This mount uses the Orbiter and Phaetus Dragonfly BMO, and also has an integrated Pinda probe mount. Hopefully, this is useful for some of you. 🙂

I plan to make a version for both Orbiter 1.5 and 2.0.

I will be releasing the files in a few days to all Patreon tiers.

Thanks,

Thomas the MakerViking

Unlock with Patreon

Unlock with Patreon